© 2022 Lyoinnovation. All Rights Reserved.

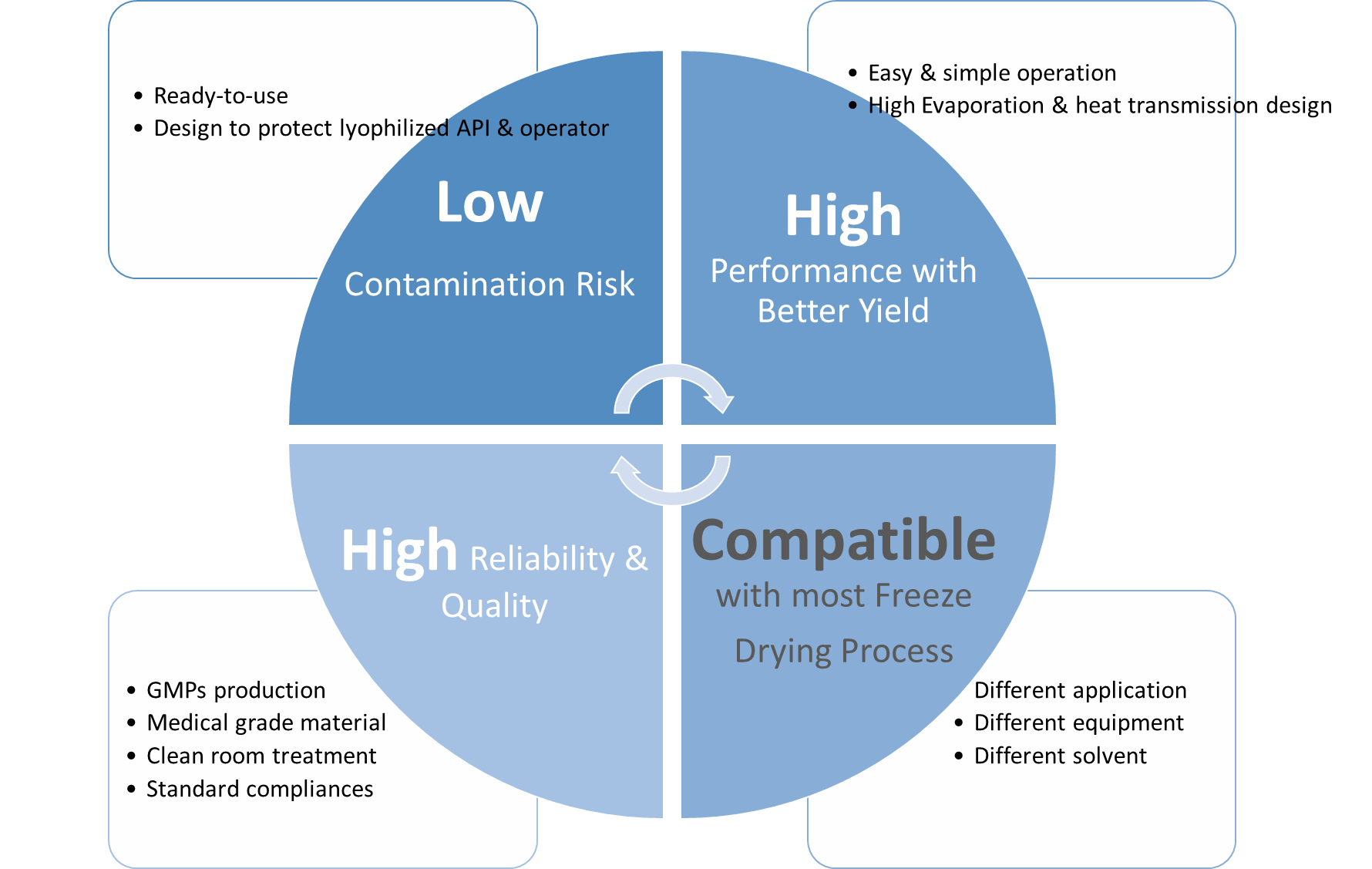

Product Key Features and Advantage

LYOINREADY® High efficiency Freeze-Drying Guard (HFG) tray has unique design engineered in supporting high heat transmission efficiency and maintaining temperature uniformity while providing excellent barrier protection and reducing fly out of lyophilized liquid API. With the key features design, LyoInReady® HFG tray has superior combination of performance advantages in efficiency and reliability.

Key Feature | Design | Advantages |

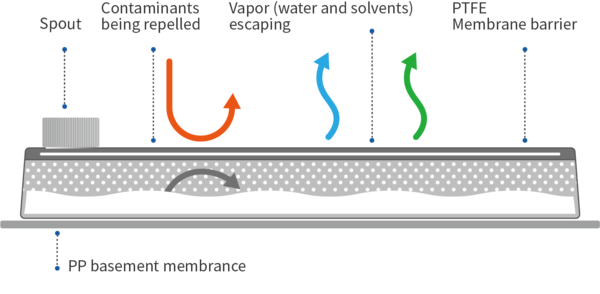

Spout | Fill-port with threaded cap made with medical-grade Polypropylene (PP) | Make tray-filling easy and convenient |

Tray top PTFE | Membrane integrated with fill-port and made with medical-grade Polytetrafluoroethylene (PTFE). It has material property of lightweight, high breathability, chemical inertness, thermal stability and non-particulating properties | Ensure seal integrity while maintaining exceptional vapor transmission rate. |

Tray bottom | Flexible bottom thin film made with medical-grade Polypropylene (PP) which has high thermal transmission rate, thermal stability and inertness properties | Maximizes contact with shelf plates, minimizing air gaps and optimizing heat transfer for efficient, uniform thermal conduction |

Sterilization treatment | Employs radiation sterilization method with sterilization standards compliance | Offer convenient, safety, and ready to use tray which can be used directly for lyophilization |

Applications

LYOINREADY® High Efficiency Freeze-Drying Guard tray is designed to eliminate a lot of cleaning operation and reduce chances of lyophilized API fly-out risk and contamination risk. And does enable greater safety in lyophilization process and improve process efficiency. Basically, the tray is suitable to different kind of batch freeze-drying and freeze-drying process development but especially worthy to clinical staging and large-scale production of biological agents such as peptides, oligonucleotides, proteins, drug intermediates, polysaccharides, strains and other active pharmaceutical ingredients and HPAPI. Also, it supports formulations for nanoparticles lyophilisation and free-drying of bacteria because of its unique features.

Quality & Reliability

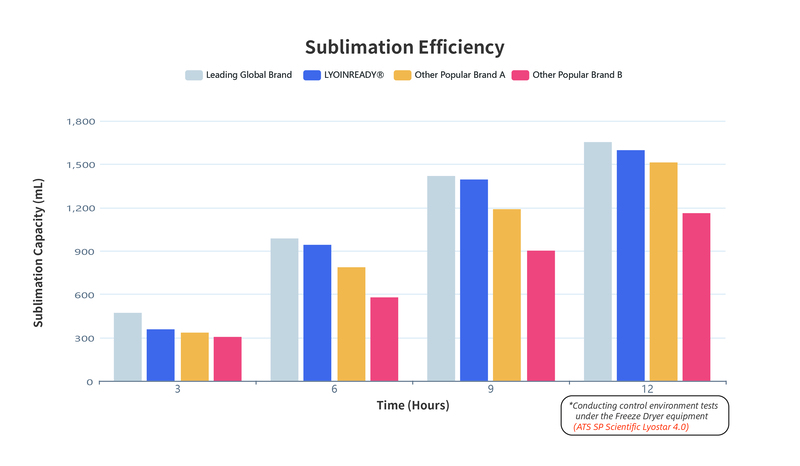

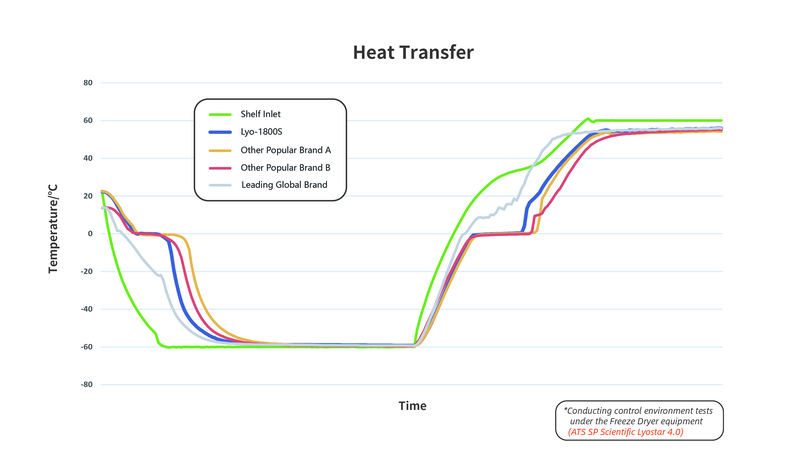

LYOINREADY® High Efficiency Freeze-Drying Guard tray is leading in performance efficiency in disposable freeze-drying tray market. LyoInReady® HFG tray shows compelling performance quality in lyophilisation efficiency test as below:

LYOINREADY® HFG tray quality is assured as it is produced under relevant Good Manufacturing Practices (GMPs) and core materials are medical grade. Also product packaging, sterilization and final inspection are conducted in a clean room environment. Moreover, product reliability is guaranteed with standard compliance as below:

Test Standard Category | Standard Specifications |

In Vivo Biological Tests | • Subcutaneous Implantation - USP 43 <88> |

Bacterial Endotoxins | GB/T 14233.2 |

Sterility Testing | ChP 2020 Part IV 1101 |

Insoluble Particulates | USP 788 |

Material Performance | • Water Vapor Transmission: GB/T 1037-2021 |